Case Studies

Case study 1: Slashing bills by 50% in a former Edge fund building

A former hedge fund building experienced unexpectedly high electricity bills despite low occupancy. The building managers sought the expertise of CarbonLnk to identify and remedy the issue. The goal was to reduce energy consumption and costs by 50%.

Objectives:

-

Identify energy losses using CarbonLnk sensors.

-

Remediate high energy consumption areas.

-

Achieve a 50% reduction in energy bills.

Requirements

01.

Understanding causes of unexplained high energy bills

02.

Identify energy losses

03.

Remediate high energy consumption

04.

Achieve a 50% reduction in energy costs

Conclusion

The intervention by CarbonLnk in the building successfully identified and addressed the causes of high energy consumption. The implementation of CarbonLnk sensors and subsequent remediation efforts led to a significant reduction in energy usage and costs, achieving the client's goal of a 50% reduction in energy bills. This case study demonstrates the effectiveness of targeted energy management and the importance of continuous monitoring and behavioral adjustments in achieving energy efficiency.

Making the case for flying electric

London Airports Centre is a Pilot training school in Essex who is focused on reducing Carbon emissions of its activities and has the ambitious goal of becoming a NetZero flight training school by 2030.

They have a fleet of electric aircraft used for their training activities as well as traditional Cessna Aircrafts.

They wanted to showcase using science-based data the difference in carbon emissions compared to traditional aircrafts. They were also interested in demonstrating how running electric aircrafts are not only green but also cheaper than traditional aircrafts.

In addition, they wanted to plan for further decarbonization by installing solar panels on the site to power the planes and further reduce emissions. To do so, they needed to understand accurately their energy profile to calculate with precision the type and number of panels needed to effectively cover all their energy needs.

Requirements

01.

Capture accurate data on electricity consumed over time

02.

Calculate CO2 emissions of flying activities.

03.

Calculate solar panels needed to meet energy needs

04.

Analyse and display Return on Investment

05.

Provide consultancy and support in solar installation

Step by step process

Planning for Net Zero

London Airsports Centre, deterred by high energy prices and the desire to further decarbonize asked us to use the data we had collected on their energy profile to produce a proposal for the installation of Solar panels on the roof of the hangar where the Aircrafts are parked.

01

Calculating the equipment needed and ROI

CarbonLnk was able to calculate the ROI and the costs of the panel over the duration of the panel warranty.

02

Match the Performance of the panel with the needs

We were able to understand precisely how many panels were needed to cover electricity needs and after further discussions it was agreed that we would install in excess of what was needed as the roof space allowed for it. We were able to graphically demonstrate an individualized panel performance graph.

03

Graphic display of performance

The performance of the panels is displayed graphically to show differences in outputs over the day and the year

*Quote and installation provided by Generation Power

Conclusion

01.

The fuel cost of a flight with an electric plane is £6.6 compared to £15.1 and £22.7 for traditional planes ( 80hP and 110 hP ) , a difference of 78% and 109% respectively

02.

The CO2 emissions reduction of flying electric is 119% reduced ( 50.8 kgs vs 162 kgs and 203 kgs )

03.

The number of panels needed are 72 to cover the needs. the ROI is 18 months if remains on current tariff or 7 years assuming variable tariff over the years

04.

The company would need to plant 9040 trees if they wanted to offset their emissions for the year.

Case study 3:

Electricity losses in former Central London Hospital

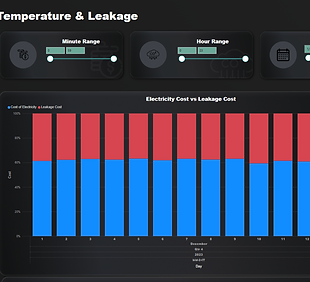

Understand high electricity bills

A former hospital building now repurposed for student accommodation is experiencing higher than expected electricity bills. The building managers need to understand this discrepancy and remedy any issues that cause the bills to be higher than normal.

The building managers have already commissioned a company to conduct an electrical testing and analysis. It did not show any discrepancies from the existing bill reading.

They asked Lnk Technologies to test the electrical installation to provide granular and real time data on electricity consumption.

Our challenge was to obtain accurate power readings from an antiquated old system without any wiring or schematic diagrams. Like most hospitals and large infrastructures, this site had the equivalent power of an electrical substation, approx. 5 MW.

We were able to show real time energy use and losses as well as make recommendations on how to improve the electrical wiring to reduce losses. We also monitored energy spikes to alert of fire hazards.

Requirements

01.

Electricity output measurement

02.

Ambient temperature measurement

03.

Electricity leakage information

04.

Electrical surges / fire hazards notifications

05.

GHG emissions scope 2 in real time

Step by step process

Conclusion

By following the recommendations, the building could have saved 38% on their electricity bills, equating to £193 per month or £2,400 annually, out of a total £6,060 annual expenditure. The detailed analysis not only helped identify the source of the losses but also provided actionable insights for immediate cost reduction and improved safety.

Case study 4:

Energy audit on a residential property

identifying quick savings

A property management company undertook a large retrofit project to improve energy ratings and achieve savings across their portfolio.

They asked Lnk Technologies to conduct an energy audits on a typical residential 3-bedroom Victorian house as a test bed to estimate potential saving across the portfolio.

We installed our IoT sensors to capture leakage and electrical inputs on the main electrical board.

For the house, our energy audit revealed that energy losses were at 15.19%. Our AI analysis identified the fridge and kitchen lighting as the biggest energy consumers.

CarbonLnk recommended replacing the fridge with an AAA* energy-rated model and installing LED lighting in the kitchen. These upgrades resulted in significant electricity savings.

Requirements

01.

Show break down of electricity consumption in the house

02.

identifying highest type of electrical loss/ consumption

03.

Recommend cost effective improvements to save energy

04.

understand health and safety audit of electrical installation

05.

calculate reduction of Co2 emissions made by improvements

.png)

.png)

.png)